October 2017 - The stars of ABC’s “Laverne & Shirley” were still making their dreams come true in Milwaukee when Pferd Inc. commenced operations in Leominster, Massachusetts, in 1979. Approximately 36 years later in the autumn of 2015, Pferd consolidated sales and marketing operations with its existing 100,000-sq.-ft. brush manufacturing facility in the Brew City. Pferd, the U.S. subsidiary of a 218-year-old Marienheide, Germany-based company called August Rüggeberg & Co., is a worldwide manufacturer and distributor of abrasives, power and maintenance brushes, power tools and consumables for workers for a wide spectrum of metal cutting and grinding and surface finishing applications.

Rick Shagoury, a senior marketing communications manager at Pferd, decided to discuss one of Pferd’s consumables called CombiClick, a quick-change disc system that is designed for use with fiber, coated abrasive, non-woven and felt discs.

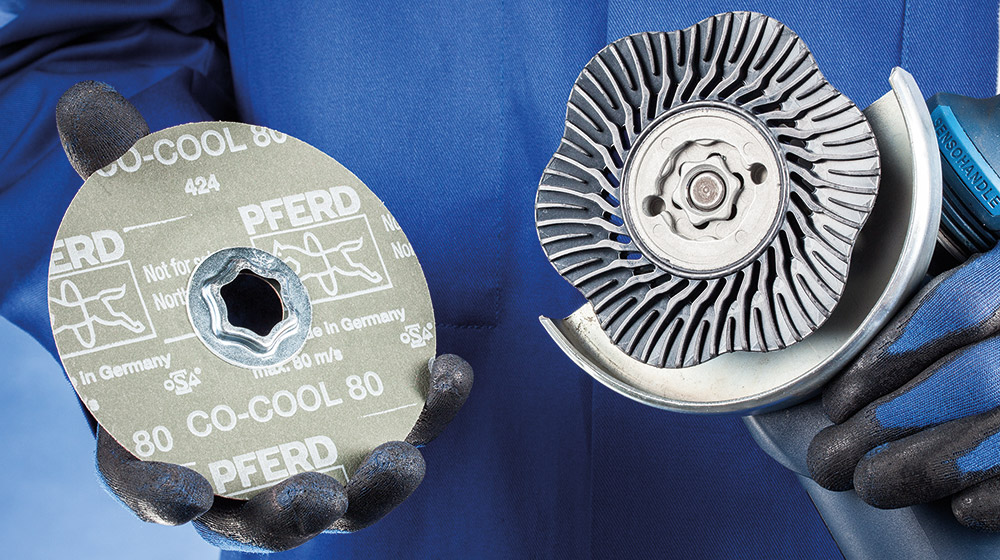

“Unlike standard fiber discs or non-woven discs, CombiClick features a single backing pad with a patented quick-change mounting system,” says Shagoury, adding that the backing pad offers a soft, flexible grinding experience that diminishes vibration and noise.

“This backing pad is also engineered with special cooling slots that reduce workpiece temperatures by up to 30 percent during operation,” he continues. “Operators can perform applications from heavy metal removal all the way to fine mirror-polishing without having to remove the backing pad from the grinder.”

CombiClick’s threaded backing pads are compatible with most angle grinders and fiber discs are available in diameters of 4, 41/2, 5, and 7 in. With its specialized geometries, the cooling slots ensure maximum throughput of air, reducing the thermal load on abrasive materials and workpieces. Its cooling system helps provide up to 30 percent lower workpiece temperatures, 25 percent increased stock removals, 30 percent longer disc life, and better use of abrasives. The combination of quick-mounting system, rugged fixture and secure disc attachment minimizes unnecessary stoppages and decrease lengthy downtimes.

“CombiClick’s quick-change backing pad drastically reduces tool change times when transitioning from applications such as grinding with a coated fiber disc to surface conditioning with a non-woven disc,” says Shagoury.

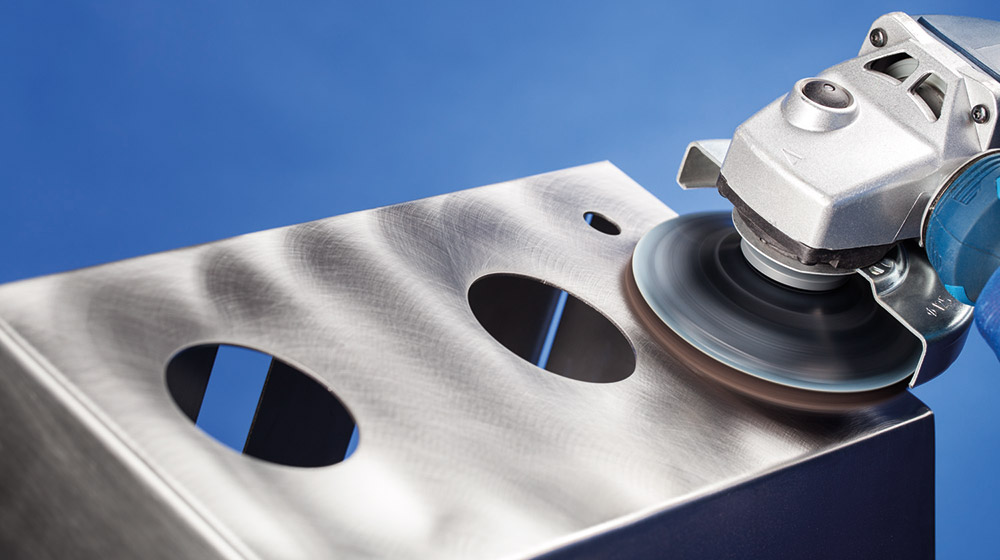

“In addition, the reduction of thermal load on the workpiece, due to the cooling slots in the CombiClick backing pad, eliminates the need for a secondary application to remove discoloration on poor thermal-conducting materials such as stainless steel,” he says. “The premium abrasive material on these discs, coupled with the lack of mounting hardware being exposed to the workpiece, means that operators can grind, finish, and polish with higher removal rates and larger surface contact areas, reducing process time and increasing operational efficiency.”

CombiClick boasts up to 25 percent increased material removal rates over a conventional fiber disc and can also reduce process costs by up to 25 percent.”

Pferd was awarded the federal prize for outstanding innovative craftsmanship for its CombiClick at the 2008 Internationale Handwerksmesse trade fair in Munich.

Perhaps more importantly, Pferd has helped countless workers in Milwaukee and across the world complete their projects more efficiently and cost effectively.

Pferd Inc.

Milwaukee

262/255-3200