Abrasive discs accommodate a wide range of applications

September 2019 - Abrasives fulfill some of the toughest tasks in metal shops. They need to be high quality, durable and contribute to an increase in overall productivity. There is greater demand for unique products that perform multiple functions, are adaptable to varied applications and are available in a multitude of specifications to accommodate a large spectrum of potential applications. And, with a continued strong emphasis on safety, end users also are requesting abrasives with attachment flexibility.

Gemtex Abrasives, a manufacturer of specialty abrasives for grinding, surface finishing and polishing, continues to work on developing products that meet even the most stringent requirements. The company’s proprietary Mini Grind R product has a one-piece, type R, plastic-back design, which makes it safer to use—and longer lasting—when compared to standard miniature resin fiber and cloth discs. Because the grain is fused directly onto the polymer backing, there is no plastic button that could detach from the disc in use, and it can be used in wet or dry applications. The polymer also promotes cool, efficient grinding.

Compared with miniature resin fiber discs and miniature two-ply cloth discs, the Mini Grind R provides longer life, says Frank Prenda, vice president sales and marketing, Gemtex Abrasives. “In addition, the operator can apply more pressure to the workpiece, it can be used in wet environments without degrading the product and is much safer due to the one-piece design,” because it lacks a button that might detach.

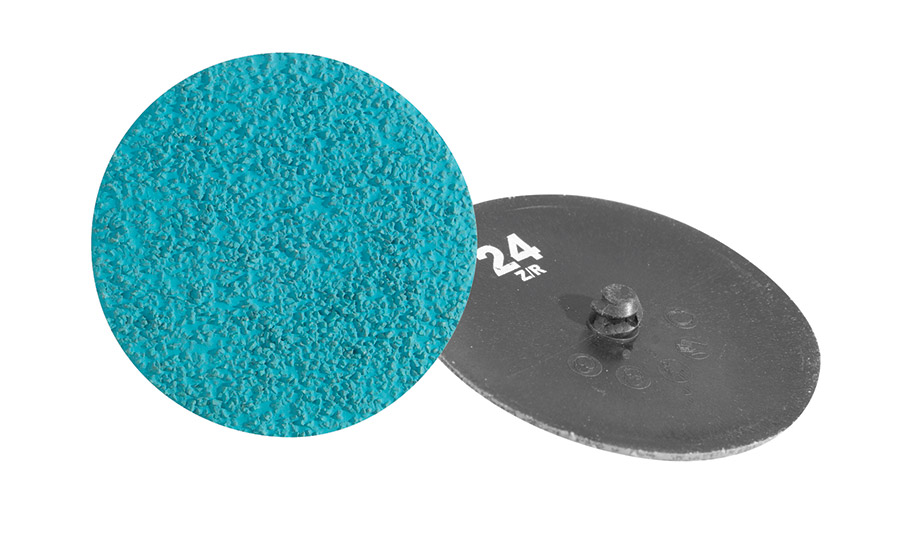

Gemtex strives to address myriad customer needs with a varied product line. One example is Trim-Kut, a patented abrasive disc with a plastic backing that can be trimmed to optimize disc life and adapt to diameter restrictions.

When the outside edge is loaded to the point where it is not grinding effectively, the material can simply be trimmed off. The discs are available in 24–120 grits in all materials and in 3 in. and 5 in. sizes for use on a drill or die grinder and 4.5 in. for use on an angle grinder. For the 3-in. and 5-in.-diameter discs, users can choose from various mandrels to accommodate all brands of tools and spindle thread configurations.

“Due to the standard 35- to 40-degree angle used in many grinding applications, the outer ¼ in. to 3/8 in. of a disc will wear away and stop cutting effectively,” Prenda says. “Although there is still a lot of grinding material left, the operator will typically discard the disc in favor of a new disc with fresh grit on the outer edge.”

The ability to trim the edge promotes full use of discs by “providing a fresh cutting edge without having to switch to a new disc,” he notes.

Trim-Kut discs are built for durability. They’re able to grind and sand a wide variety of materials quickly and stay cool. Gemtex’s patented process of fusing premium abrasive grains to a durable polymer backing means there’s no need for a backing pad.

“Gemtex manufactures abrasives with a unique process, which provides the ability to customize formulations based on customers’ needs,” Prenda says. Gemtex’s 43 years of experience makes the company a preferred coated abrasives supplier for numerous specifications. “Many end users are not aware of the new abrasive technologies available, so they rely on Gemtex to meet their common objectives of quality finished products manufactured with efficiency.”

Gemtex Abrasives

Toronto, Canada

800/387-5100