Displaying items by tag: ceramic

Tough edges

High-quality ceramic grains provide increased performance

Flap discs for aggressive grinding applications

February 21, 2019 - Weldcote Metals, Kings Mountain, North Carolina, a division of Zika Group, introduced its line of C-PRIME and C-PRIME PLUS ceramic flap discs.

Weldcote’s C-PRIME flap discs feature strong polyester backing for aggressive grinding applications that do not require excessive flexibility. The C-PRIME PLUS flap discs feature an industry-first, poly-cotton backing with high-quality ceramic grain, which provides excellent stretch and flexibility, while adding enough strength to maximize the aggressive cutting points of ceramic grain.

The ceramic grains in Weldcote’s line of flap discs contain a grinding aid for cooler running temperatures, which reduces the risk of discoloration and heat-induced deformations of the final workpiece. These ceramic grains are also self-sharpening, which allow them to be used for longer periods of time than similar flap discs on the market. The C-PRIME flap discs are available in 4 1/2 in. and 7 in. sizes, and the C-PRIME PLUS flap discs are available in 4 1/2 in., 5 in. and 6 in. sizes.

“The C-PRIME PLUS flap discs feature a proprietary compressed design that gives the user a tough edge, increased performance and 50 to 60 percent higher stock removal rates over standard ceramic flap discs,” said Joe O’Mera, CEO of Weldcote. “These increased removal rates can provide significant savings and increased productivity for our customers in the field.”

Weldcote Metals

Kings Mountain, North Carolina

704/739-4115

Tiger wheels built for biggest challenges

September 12, 2018 - Get the most demanding jobs done right and done fast with abrasives designed with your biggest challenges in mind. Whether you’re looking for serious stock removal on hard to grind metals, working with aluminum, or performing precise cuts on thin metal, Tiger Ceramic, Aluminum, and UltraCut wheels will get it done for you.

- Tiger Aluminum wheels are specifically designed for high performance cutting and grinding on aluminum. These wheels blend abrasive grains with Weiler’s non-loading formula, resulting in a fast and consistent cut rate on aluminum.

- Tiger Ceramic wheels leverage a self-sharpening Ceramic Alumina grain that delivers a superior combination of life and cut rate. Ideal for stainless steel and other hard-to-grind metals.

- UltraCut 1mm cutting wheels deliver lightning fast, super smooth, clean cuts on sheet metal, tubes, profiles, and small cross-section rods.

Weiler Corp.

Cresco, Pennsylvania

570/595-7495

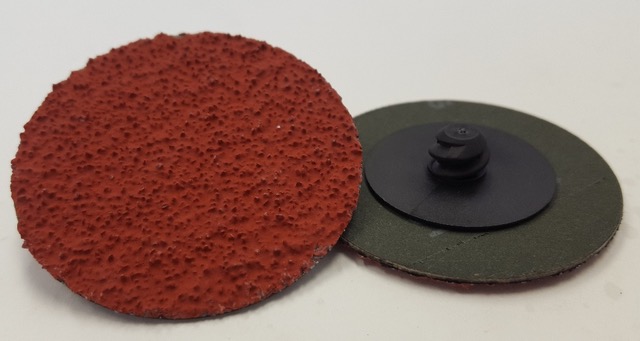

Discs feature a high concentration of ceramic grain

June 7, 2018 - Mercer Industries recently released its next generation of premium ceramic products with the introduction of Ceraflame 2™ Resin Fibre Discs. These discs feature a high concentration of ceramic grain lasting 40% longer than the original grain. Ceramic, a premium man-made grain that self-sharpens throughout its life, is the longest lasting, coolest cutting abrasive in the Mercer Industries line.

These new resin fibre discs are specially formulated to be used on high performance alloys, high carbon steel, stainless steel, non-ferrous metals and heat sensitive metals. They have a heavy-duty vulcanized fibre backing and a top size coating for cool, fast cutting. Available in grits from 24 to 80, they can be used to strip, grind, debur and polish. The discs are contaminant free to prevent stainless steel from rusting and will not stain or burn material.

Ceraflame 2™ Premium Ceramic Resin Fibre Discs are available in 4 ½ in. by 7/8 in. hole with a max RPM of 13,300.

“We are excited to be able to offer Ceraflame 2™ to the marketplace,” states Gayla Brainerd, Director of Sales. “We work closely with our customers to develop products that fill requirements that are not necessarily being met by the current products on the market. This is a natural progression of the Ceraflame™ product line, providing our partners with a premium offering to help satisfy their customer’s needs.”

Mercer Industries

Ronkonkoma, New York

800-221-5202

www.mercerindustries.com

Ceramic Ultra-X discs

May 15, 2018 - The new Ceramic Ultra-X grain is manufactured in a new way that results in a much finer crystalline structure. Such a unique mineral fracture provides the abrasive product with a longer life, and more aggressive grains with an improved self-sharpening effect.

Significant performance advantages include a higher metal removal rate at faster cutting speeds with a lower grinding temperature and less friction. All of which correlate to shorter cycle times and less disc changes, resulting in reduced cost per part and an excellent cost/performance ratio.

In addition, the Ceramic Ultra-X line is top-sized. A top-sized product can positively impact the workpiece through a reduction in metal discoloration/oxidation, as well as minimal heat related stress cracks. It can also benefit the abrasive through reduced loading, glazing and dulling.

Gemtex Abrasives

Toronto, Canada

800/387-5100

www.gemtexabrasives.com

High-performance abrasive wheels

Tiger Ceramic wheels have ceramic grains that self-sharpen at a higher rate than other grains. The result is a higher material removal rate, faster cutting speeds, cooler grinding and reduced friction at less pressure. Lower temperature and less friction reduces heat discoloration of the workpiece and translates to a smoother cut and less kickback during operation.

Weiler Abrasives Group

Cresco, Pennsylvania

800/835-9999

Wheels offer durability and better finishes

Gemtex expanded its non-woven product line with a “Premier” Ceramic Strip Away wheels. The wheels are made in North America with high quality standards to provide cool cutting surface removal with long life and a better finish on stainless steel, titanium and all heat-treated metals. The Premier range consists of type 1 wheels, type 27 wheels, type R quick-lock style and spindle-mounted wheels. Diameters range from 2 in. to 8 in.

Gemtex Abrasives

Toronto

800/387-5100

www.gemtexabrasives.com